The KAIROS project successfully presents the first milestone to boost AI and Industry 4.0 in the naval sector

Efficient manufacturing of large parts is one of the challenges facing the shipbuilding industry. The KAIROS project is an exciting initiative that seeks to investigate cutting-edge technologies in composite manufacturing, Industry 4.0 and digital twin to develop a solution for the efficient manufacture of large composite parts for the naval sector, with a high degree of automation, as well as quality and cost optimisation.

On 17 January, CT Ingenieros hosted a visit from CDTI to evaluate the first milestone of the KAIROS project, in which a multi-sector and multidisciplinary R&D consortium is participating, coordinated by CT Ingenieros, Izertis, Segula, Sofitec, SP Consultores y Servicios, Cramix and Global Vacuum Presses. AIR Institute participates as a research institute together with ITCL Technology Centre, the Advanced Centre for Aerospace Technologies (CATEC), the University of Cadiz and Gaiker.

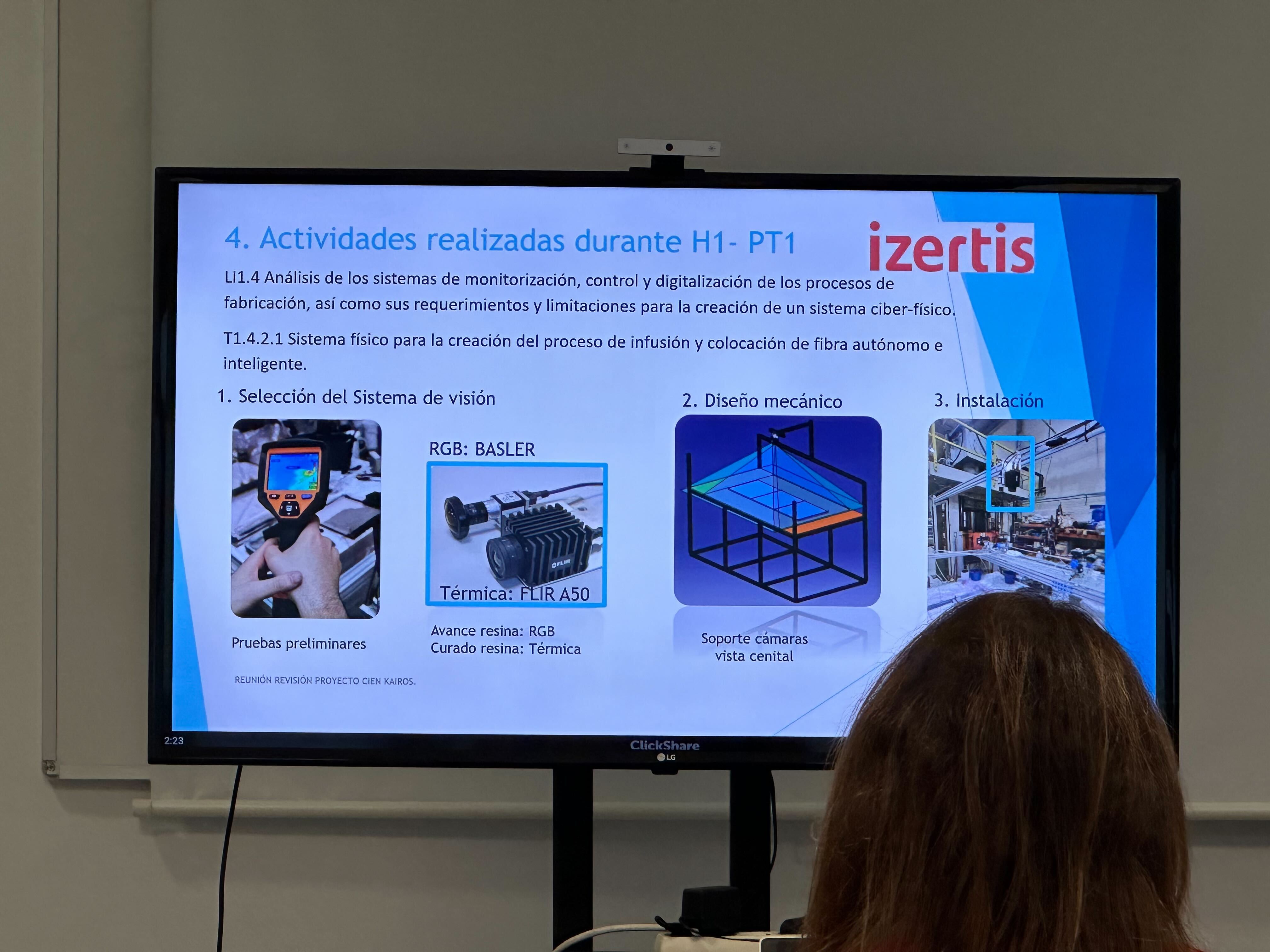

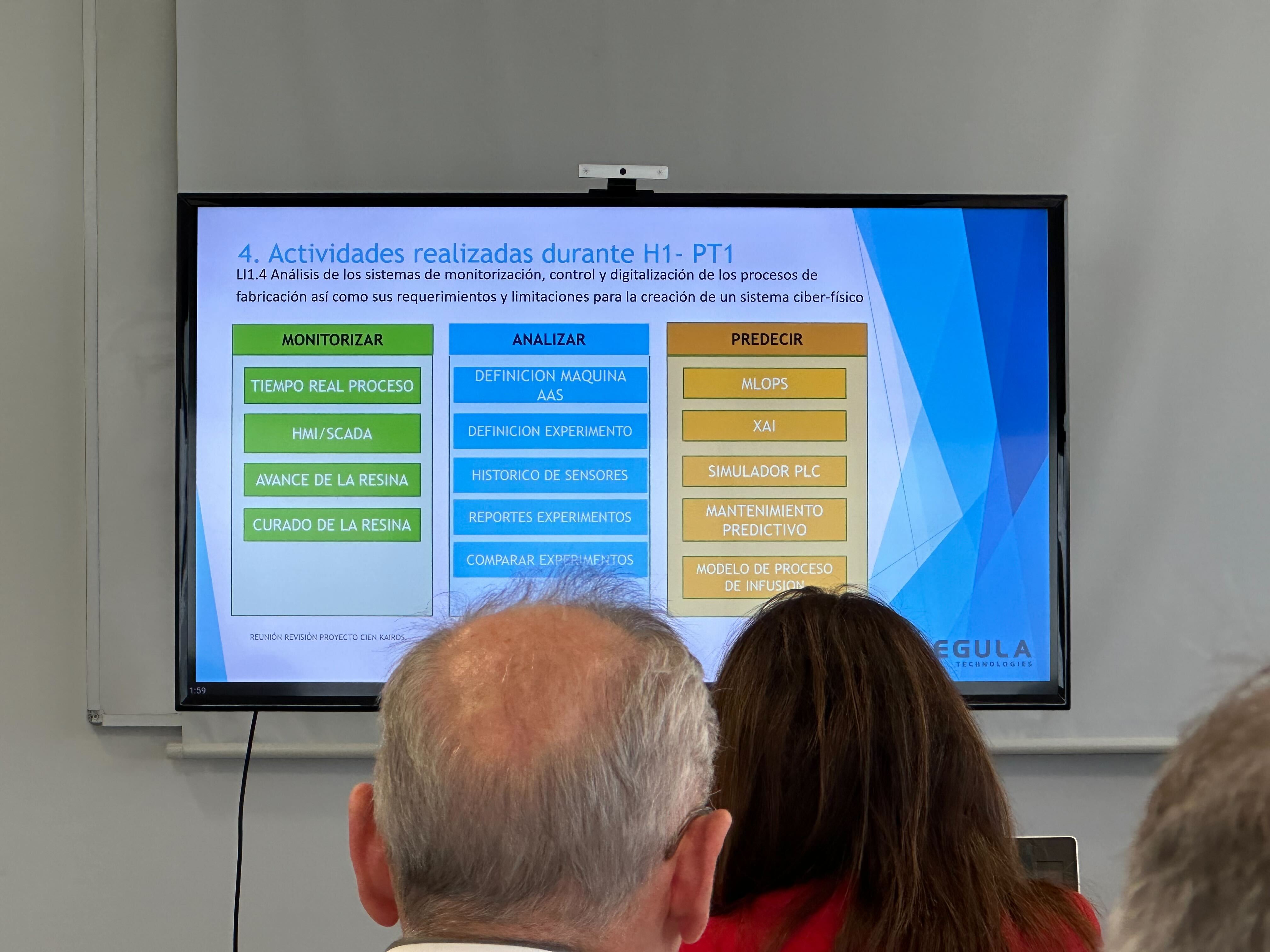

KAIROS represents a significant technological advance in the intelligent monitoring and control of the infusion process of large composite parts, as it will work on the automation of an infusion process assisted by sensors and artificial vision, while providing a digital model of the process. All of this will be applied to a ship loading gate as a use case.

New technologies play a key role in this project, from automated manufacturing processes, machine vision, sensorisation, artificial intelligence (AI) to digital twinning. AIR Institute's participation is based on the collection and analysis of digital and physical tools and technologies for the creation of digital twins, enabling process control and predictive maintenance, including edged computing architectures, industrial internet of things (IIoT) technologies and data analytics techniques using explainable artificial intelligence (XAI).