Meeting on the progress of the Expand IntelWines project

The development of the Expand IntelWines project is proceeding according to plan. The team members have met to discuss the progress of the project, and to define the next steps to be taken.

Over the months that have passed since the last update of the project, progress has been made in the realisation of the artificial intelligence algorithms necessary for the optimisation of the boxes placed on the pallet. Heuristics have been obtained that allow the hyperparameters of the neural networks to be adjusted. Once these have been obtained, populations of individuals have been simulated with neurogenic algorithms that have been improved over different generations.

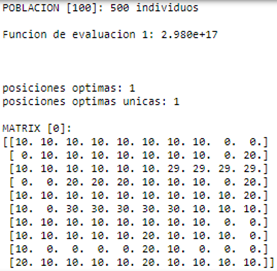

As can be seen in the image below, populations of 500 individuals have been simulated, which have been improved over the iterations.

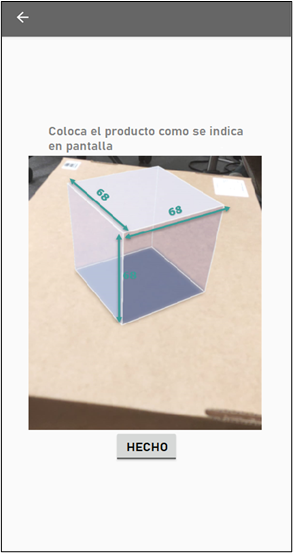

The conclusion of these experiments has been a first version of the neurogenic algorithm that is able to calculate the best position for the boxes of products before placing them on the shipping pallet, and this information is provided to the operator in an application interface on his mobile device.

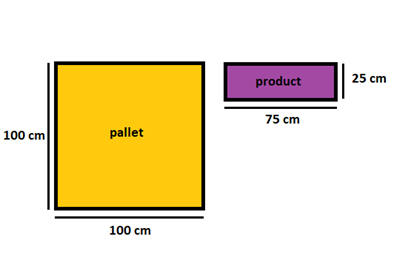

It is expected to reduce its calculation times in future versions, as well as to test the impact on the operators' work. The image shows a simulation of how the application indicates the position in which the product should be placed inside the shipping pallet so that it is not damaged during the journey and the number of pallets to be used in these shipments is reduced.

Some details are yet to be completed in order to meet all the objectives that have been set. However, significant progress is being made in order to optimally arrange boxes on each pallet during the palletizing process.

About Expand IntelWines

The project aims to develop new Artificial Intelligence techniques and implement them in wineries’ production, supporting decision making and improving food safety: A new intelligent palletizing system for the optimization of winery logistics.

The project is being deployed at the Pago de Carraovejas wine company, which was founded in the 1970s and has gained recognition for its quality wine thanks to its efforts to establish a high level of control over all its production processes. The company is currently undergoing digitalization and implementing, amongst other features, a platform for product traceability at all the stages of the wine value chain, from the vineyard to the consumer's glass, in order to optimize resources, reduce costs and improve quality and food safety.

However, one of the processes in which Pago de Carraovejas has detected the most room for improvement is product palletization. Once the bottles of wine have been labelled and packed in boxes holding different amounts of wine, they are reserved in the winery's warehouse. In this regard, Pago de Carraovejas is seeking a solution to increase the load capacity of each pallet, thus reducing the number of pallets needed for shipments and lowering transportation costs.

This project has received funding from the European Union's Horizon 2020 research and innovation program through the open call EXPAND SmartAgriHubs within the SmartAgriHubs project, funded through grant agreement No. 818182 (call H2020-RUR-2018-1).